MUMBAI – Godrej & Boyce, a distinguished leader in Indian industry, proudly announces a groundbreaking innovation by its Godrej Aerospace division. The company is pioneering a high-temperature brazing process essential for advanced Aero Engine manufacturing – a significant milestone for Indian technological self-reliance.

his achievement underscores Godrej Aerospace's commitment to driving innovation and fostering indigenous capabilities within India's rapidly developing aerospace sector.

Reducing Foreign Reliance

The development of this high-temperature brazing process offers a two-fold benefit: it establishes a vital new capability for India's aerospace industry and simultaneously reduces the nation's reliance on external technologies.Addressing Critical Aerospace Needs

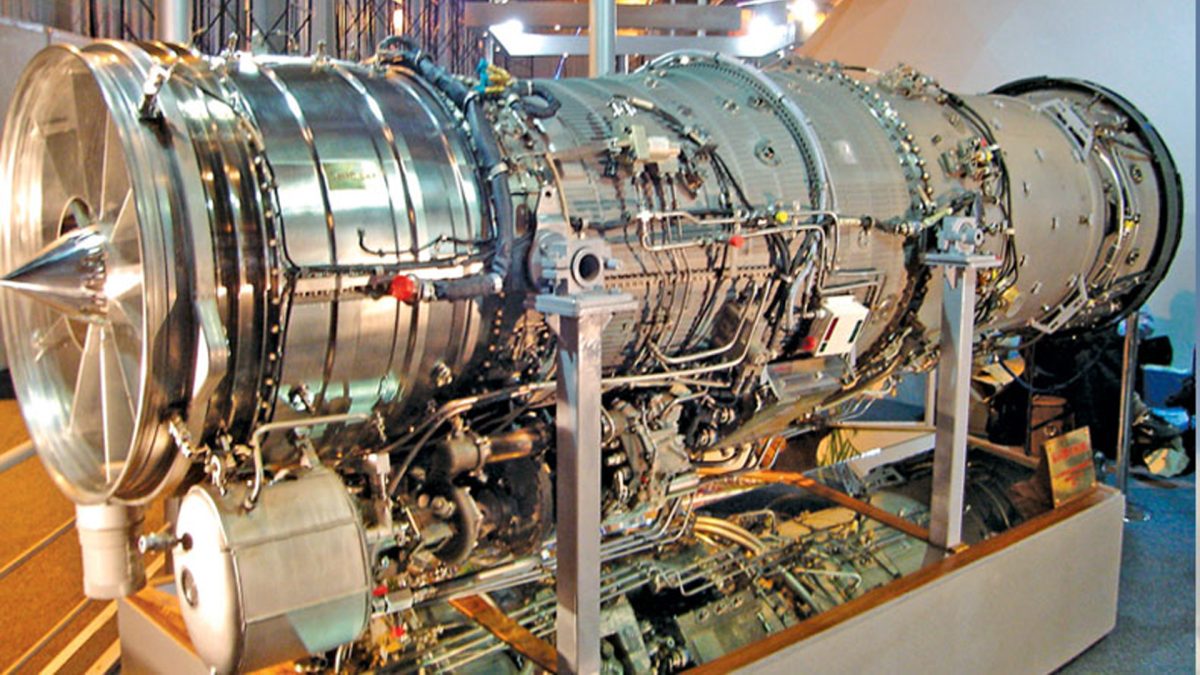

Aero Engines function within environments characterized by extreme heat and pressure. Their turbine rotor blades require specialized techniques to withstand such conditions while ensuring peak operational efficiency.Godrej Aerospace's high-temperature brazing process is tailored to seal the tip and root openings of these cast turbine rotor blades. This sealing supports the ceramic cores that create serpentine cooling passages, a necessary network for cooling air to flow within the blades.

Statement of Leadership

"This milestone represents a significant leap forward in India's aerospace capabilities," remarked Maneck Behramkamdin, Senior Vice President & Business Head of Godrej Aerospace. "By developing this process indigenously, we are not only meeting the stringent requirements of modern aerospace technology but also showcasing India's potential in advanced manufacturing techniques."A Legacy of Indian Innovation

Godrej & Boyce, since its founding in 1897, has been a cornerstone of Indian economic growth and self-sufficiency. Its investments in complex engineering, innovation-driven design, and sustainable manufacturing have helped expand critical sectors like aerospace, energy, and security. The globally recognized company continues to contribute to India's space endeavors, clean energy initiatives, and green building infrastructure.Note on Brazing: Brazing is a vital manufacturing process. It joins metal components by melting and flowing a filler metal into a joint. High-temperature brazing uses specialized filler materials that can endure the extreme conditions experienced within aero engines.